Disclaimer: John Deere covered my expenses for this trip, but they did not compensate me for this post.

*******

How We Run

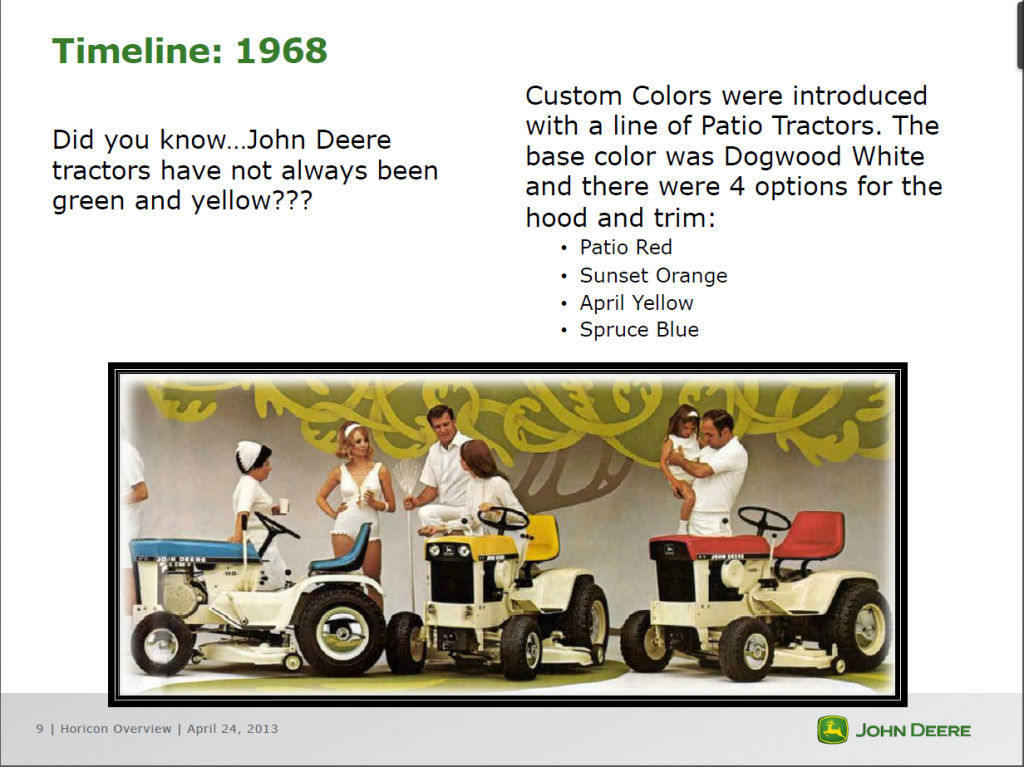

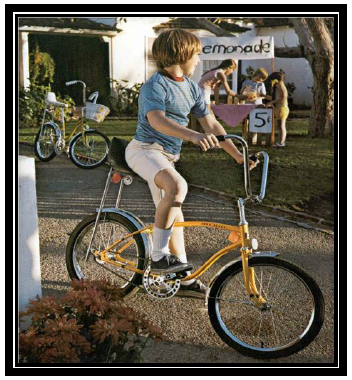

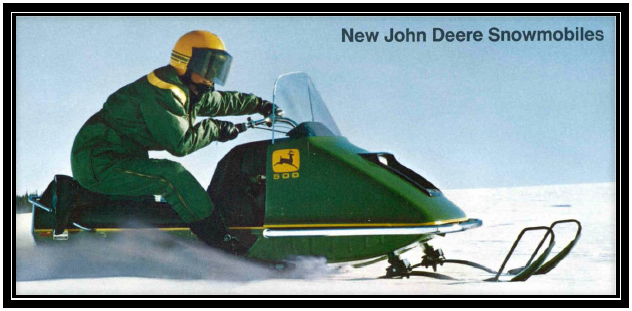

Did you know that John Deere tractors weren’t always their iconic green and yellow? Did you know that John Deere for a short time made bicycles? Or that John Deere also made snowmobiles? And, in fact, it was the marketing campaign for those snowmobiles that actually spawned one of the company’s most recognizable slogans … Maybe you have heard it?

Nothing Runs Like a Deere

Now, I won’t go too far into the short-lived line of tractors designed to match your patio furniture, nor will I delve into the company’s brief experiment with the electric riding mower (Really!) … instead I will tell you about the one common thread. That equipment, you see, produced in the John Deere Horicon Works facility in Horicon, Wisconsin.

I had the opportunity for a brief visit and tour of Horicon Works last week. Located about 45 minutes northeast of Madison, on the edge of the Horicon Marsh, Horicon Works has been John Deere’s flagship factory for more than 100 years. Horicon Marsh, I’ll mention, is the largest freshwater cattail marsh in the US and the town of Horicon is smack dab in the center of Packers Land. (Maybe only a slight coincidence that these two organizations share the same iconic colors.)

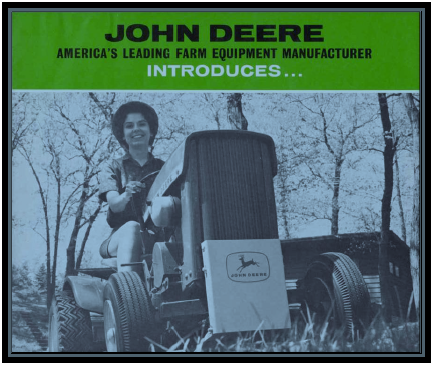

While the plant itself has a long history, John Deere Horicon Works has been the home for John Deere Lawn Equipment since 1963. And anyone quick with the math knows that that makes, yep, 50 years. Fifty years since their first lawn tractor (tagged as the 110) rolled off the lines.

John Deere 110; no. 60

The town will celebrate this summer a Weekend of Freedom Machines – the 50th Anniversary Celebration of Deere’s Lawn and Garden Tractors.

*******

Cheese?

You might ask. … Well, I didn’t really see any. Brats … yes! Cheese … No!

What I did see was a finely-tuned, wholly American manufacturing plant (1400 employees strong) in action. And fighting back a spastic chant of “U.S.A. U.S.A….”, by 2012 – John Deere Horicon Works had produced some 9 million products, shipping and selling in all parts of the world.

*******

Editor’s Note: For more from the experts at John Deere see our articles on the basics: Mower Maintenance & Grass Cutting Best Practices.

The Tour :: Stamping Steel

After we suited up, our tour started in the 201,000 sf Department 101 – the company’s world class stamping facility. We saw bone shaking machines, hi-tech lasers and an almost inconceivable amount of cast and die sets – racks and aisles, one after another – around 4400 sets in total.

This plant handles needs throughout all of Deere, working some 50,000 tons of steel last year – resulting in 26 million individual pieces. This high capacity operation can handle two-ton steel coil stock. But it is the stamping method, and their attention to steel chemistry, which allows for Deere’s signature “deep deck” – formed from steel … plates.

Robotics appear throughout. Steel bought mill direct and used to make both production and services parts. The entire operation seems to remain true to the legacy of John Deere, the man himself – a New England Blacksmith with a “knack for solving problems.”

*******

The Tour :: Powder Coat Paint

Parts stamped in 101 (above) make their way to the “Paint Building,” technically part of the downtown 201 facility. Some 9 miles of conveyor wind in and out of this space. Parts of all kinds are painted in each available color (Black, Deere Green and Egg Yellow). The word “ballet” comes to mind watching them all move.

Deere incorporates a powder type coating method, similar to what you might find in the automotive industry – we witnessed this first hand. All parts are prepped (and painted), before assembly, in a 4-part process. The most intriguing step of which is a special E-Coat – a treatment applied to help inhibit rust.

Paints are oven-baked and electro-statically charged (similar maybe to galvanizing). Each rack along the conveyor is bar-coded. Using sensors throughout the chain, a computer is told what to paint … what.

*******

The Tour :: Making Tractors and … Zs

More: For our report on test drives of this equipment, please see our article – The Ride and Drive Event.

* X300 and X500 Select Series Factory Line

Continuing into the main portion of the 1.2 million sf Building 201, we witnessed the assembly of their x300 Select Series Lawn Tractor and the x500 Select Series Garden Tractor. A floor-sensing, “smart car” conveyor system whips machines to different stations within the assembly process.

* EZtrak Factory Line

The EZTrak line stopped us shutter bugs in our tracks. It was at the end of this line that a chunk of Deere’s How We Run commercial was shot. Unlike their other equipment, the EZTraks (or Zs as they are called) have one purpose and only one purpose in mind. These are lawn cutting machines. Released by Deere initially in 2007, only after extensive trial and error used to minimize cost.

* X700 Signature Series Factory Line

The company’s pride and joy – x700 Signature Series … for those that want a luxury mow. We heard of some of the design considerations that went into this tractor mower (and I will get into these next time). The company designs all their machines to fit those from the 5% female @ 4’10” up to the 95% male @ 6’5”.

A tractor loads every 8 minutes.

*******

The Tour Playlist

Editor’s Note: For more Factory Tours from Building Moxie, please see our Category – Tours.

John Deere Lawn Equipment

Horicon’s riding equipment portfolio includes:

- EZtrak™ Mowers

- X300 Select Series™ Tractors

- X500 Select Series Tractors (adding a 4 year warranty)

- X700 Signature Series™ Tractors

- Riding Lawn Equipment Attachments

- John Deere’s Shop on Amazon

We had to opportunity to test them all, plus the D100 Series – made however in Greeneville,TN (as well as some top competitors’ equipment) at a “Ride and Drive Event” immediately after our tour.

But more on this next time. (As pictured below, we test drive some of Deere’s popular offerings and compare them to those from other leading manufacturers.)

courtesy of John Deere

*******

For more on lawn care from us, please see our category – Lawn. For part two from this visit – John Deere Test Drives and Review. Thanks. ~jb

Still using a 1968 Spruce Blue 314, 14 hp. with hydrostatic drive.

that is a testament in itself. And I could be wrong but I think we might have some pics up in here that feature it. cheers Thomas.